The Department of Mechanical Engineering from the day of its inception, has been taking long strides in the field of science and Engineering. One of the oldest and active departments anticipated the rapid developments in Technology and software and provided the most sophisticated laboratory facilities & excellent infrastructure. The department has well qualified dedicated enthusiastic teaching & technical staffs along with staffs from ISRO.

It is a discipline that finds wide scope in emerging areas like CAD, CAM, CIM, Robotics, Mechatronics, and Renewable Energy etc. The Department is provided with state-of-the-art laboratories and workshops. The Department organizes a number of workshops, seminars, conferences (University, state, and national level) every year. The students of our department have good communication and Inter personal skills. Their thoughts and creativity has yielded them many State and National level prizes.

We, staff members shall strive hard to impart knowledge and state of art training to our students and to expose them to the current and broad areas of Mechanical Engineering namely design, manufacturing, energy and thermal science so that they can later practice their profession both at home and abroad and be instrumental in bringing out overall technological developments for the nation.

To impart quality education to the students in order to

Graduates will be able to

| S.NO | STUDENT NAME | NAME OF THE COLLEGE | NATURE OF THE EVENT | DATE | PRIZE |

|---|---|---|---|---|---|

| 1 | PIRUTHIVIRAJ T | SNS COLLEGE OF TECHNOLOGY | PAPER PRESENTED 1st & | 2nd Feb 2017 | – |

| 2 | PRAKASH K | ||||

| 3 | HARISH UDAYA KUMAR S | SNS COLLEGE OF TECHNOLOGY | CAD MODELING & WORKSHOP | 1st & 2nd Feb 2017 | – |

| 4 | MANOJ S | ||||

| 5 | PRAKASH K | ||||

| 6 | AZHAGU SIVA N | ||||

| 7 | JOBIN K THAMPI | ||||

| 8 | RIYAZ M D J | ACADEMY FOR MANAGERIAL | EXCELLENCE CREATURA-NEW PRODUCT DEVELOPMENT | 24th Feb 2017 | Rs. 6000 Cash prize |

| 9 | HARISH UDAYA KUMAR S | COIMBATORE INSTITUTE OF ENGINEERING AND TECHNOLOGY | WORKSHOP | 24th Feb 2017 | – |

| 10 | DINESH KUMAR | ||||

| 11 | ANANTH K | ||||

| 12 | ARAVIND K | ||||

| 13 | RAJESH KANNAN M | IIT MADRAS | WORKSHOP | 5th – 9th MARCH 2018 | – |

| 14 | RIYAZ M | SRI KRISHNA COLLEGE OF TECHNOLOGY | TECHNO-TALK | 10th & 11th March 2017 | 1st Prize |

| 15 | RIYAZ M | SRI KRISHNA COLLEGE OF TECHNOLOGY | STAIN OF CRIME | 16th & 17th March 2018 | Rs. 2000 Cash Prize |

| 16 | PIRUTHIVIRAJ T | COIMBATORE INSTITUTE OF TECHNOLOGY | WORKSHOP | 1st Sep 2017 | – |

| 17 | PRAKASH K | ||||

| 18 | RIYAZ M | ||||

| 19 | RAJESH KANNAN M | KUMARAGURU COLLEGE OF TECHNOLOGY | YUGAM | 7th – 11th Feb 2018 | – |

| 20 | PRAKASH K | ||||

| 21 | PIRUTHIVIRAJ T | ||||

| 22 | RIYAZ M | ||||

| 23 | PIRUTHIVIRAJ T | SNS COLLEGE OF TECHNOLOGY | WORKSHOP | 15 & 16th March 2018 | – |

| S.NO. | FACULTY NAME | TITLE OF THE PAPER |

| 1 | Dr.P.Dharmalingam | Augmentation of Solar Cooker with Single Basin Single Slope Solar Still for Productivity Enhancement – An experimental Study |

| Biological Synthesis of Zinc Oxide (ZnO) Nanoparticles using Eucalyptus Leaves | ||

| 2 | Mr.S.A.Gokulakrishnan | Design and Fabrication of Digital Fuel Indicator for On-road Vechicles |

| A Study of literature review on dynamic characteristics and vibration analysis of on-road vehicle chassis by multibody simulation approach | ||

| 3 | Mr.S.Arun Babu | An experimental investigation on the effect of ZnO/water nanofluid on the efficiency of flat-plate solar collector. |

| Biological Synthesis of Zinc Oxide (ZnO) Nanoparticles using Eucalyptus Leaves |

The department has well contended labs, excellent infrastructure and dedicated team of faculty members to impart practical knowledge to the students in better way. It as simulates all the facilities and equipment’s that inculcate modern trends and application of Mechanical Engineering to the students. The following are the laboratories in this department.

With excellent infrastructure, the DMC is equipped with Pentium IV processor supporting 40 nodes, software’s like Auto CAD 2000, Pro-Engineer, Mechanical desktop with power pack, virtual NC Quest, AMD, Pro/Mechanica, NISA, Master CAM, I-DEAS, ADAMS, AnsysEd.

The laboratory is established with all types of modern equipments like Diesel engines with various loads, Petrol Engines with various loads, Air Conditioning unit, Air compressor, Boiler, Refrigeration unit and various Heat Transfer Equipments.

The laboratory is established with all types of modern equipments like Diesel engines with various loads, Petrol Engines with various loads, Air Conditioning unit, Air compressor, Boiler, Refrigeration unit and various Heat Transfer Equipments.

Metrology lab is equipped with CMM, Optical profile projector, floating gauge micrometer, optical tachometers, digital vernier calliper and micrometer, auto collimators, comparators, thread measurement gauge, form measurement, toolmaker’s microscope, torque measurement etc.

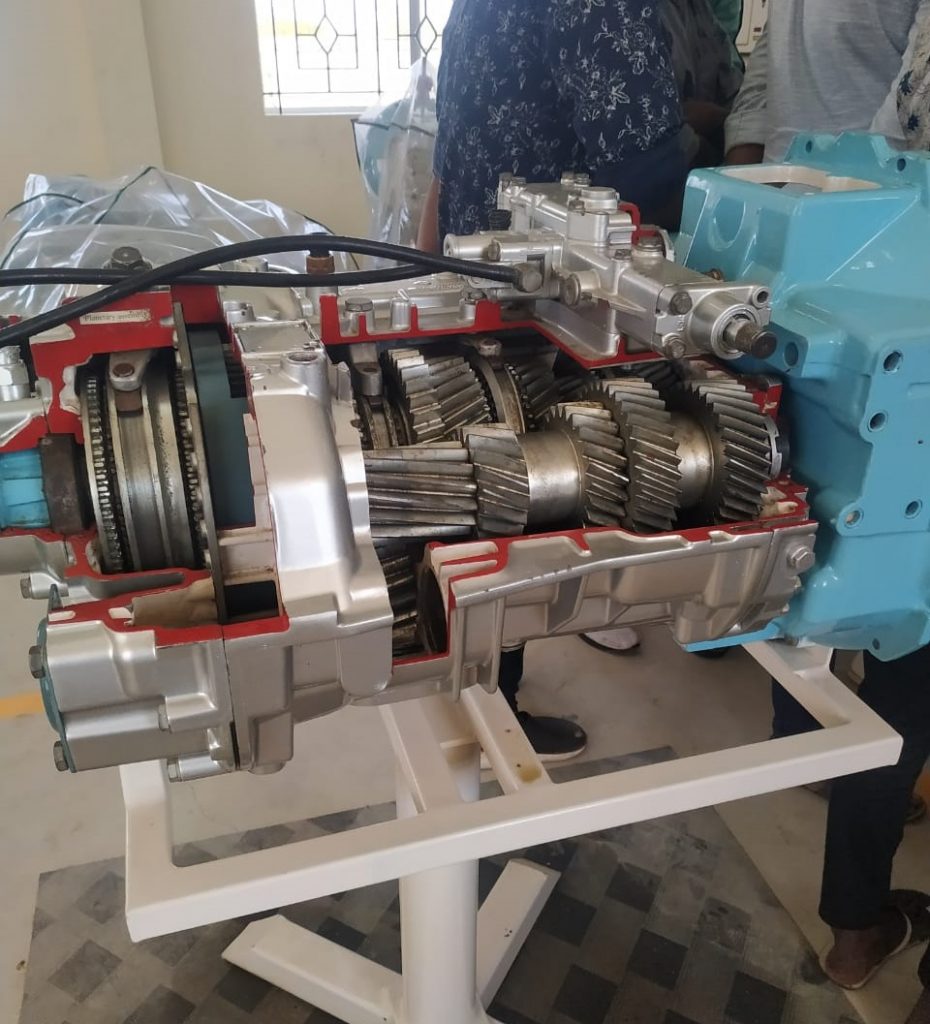

To impart practical knowledge on design and analysis of mechanisms in the machine tools and automobiles. In Machine Dynamics Lab, the students are doing the experiments related to their theory subjects like Engineering Mechanics, Machines and Mechanisms and Fundamentals of Vibration and Noise. Various equipments like governors, gyroscopes, balancing machines and universal vibration facilities are available to understand machine dynamics.

The Department of Mechanical Engineering is a well-equipped department library is functioning in the department catering to the needs of the faculty and students for both academic and research work. The Library was started in the year 2000 with around 200 volumes, now it has around 800 volumes

| S.NO | DATE | EVENT | TOPIC | CONDUCTED BY |

|---|---|---|---|---|

| 1 | 19.10.2023 | Innagural function | MEA - innagural function | Mr.PRABHU, CADD Infotech, Coimbatore |

| 2 | 13.02.2023 | Seminar | Roadmap to industrial revolution | Mr.SURESH, Ass. Manager, LG Equipments, Coimbatore |

| 3 | 21.09.2022 | One day Seminar | International Peace Day | Sr.Lourdu Sagayam Director-MarialayaRehabilitation home for Children & Women |

| 4 | 14.05.2022 | National Level Technical Symposium | EMICA 2022 | M.Satis Babu,GM(International BusinessDevelopment),Kavin Engineering and Services Pvt.Ltd,Coimbatore |

| 5 | 23.04.2022 | Seminar | Preparation Strategy for Gate Exams | A.Saravanakumaran,Gateforum Engineering Success |

| 6 | 30.03.2022 | Internal Hackathaon | Internal Hackathaon for ME 2022 | Dr.P.Dharmalingam, HOD MECH |

| 7 | 3.09.2021 | Webinar | Essential Life Skills and Entrepreneurship Skills | R.Sathishraj Founder and CEO,E-Crusaders,Chennai. |

| 8 | 8.3.2018 | Wild track racing –WTR | RACING | Dr .Anusha .R ,CEO, TCE |

| 9 | 7.3.2018 | Symposium | ERUDITE 2K18 | T. Velliangirinathan B.E (Mech) Founder & CEO ,Howzzat traders ,Pollachi |

| 10 | 14.2.2018 | Guest lecture | Engineering materials and metallurgy | Dr .G. Suresh Kanna , Associate Professor Coimbatore Institute of Technology,Coimbatore |

| 11 | 14.2.2018 | Guest lecture | Finite Element Analysis | Dr N.V.Dhandapani .Associate Professor Karpagam college of Engineering ,Coimbatore |

| 12 | 05.1.2018. | Industry Visited | Logistics | Mr.B.Prakash ,Head of the Department Ntc Logistics Ltd, Namakkal |

| 13 | 2.08.2017 | Association Inaugural Function | Erudite 2k17 | Mr. Guruselvaraj (HRM), (DGM) “Flowlink Systems Pvt Ltd , ARASUR” |

| 14 | 9.08.2017 | Workshop | Industrial Fire and Safety Engineering | Mr .K Ravi Shankar Institute of Industrial Fire and Safety Engineering |

| 15 | 4.08.2017 | Guest lecture | RIVET – Mechanical Electrical Plumbing | Mr .Anand (MD), Coimbatore |

| 16 | 31-07-2017 | Guest lecture | Automotive Dynamics & Designing | Mr . Prashanth.T, Coimbatore |

| 17 | 31.07.2017 | Guest lecture | CREO – Advanced modeling | Mr. Lawerence, Coimbatore |

| 18 | 028.07.2017 | Guest lecture | CATIA -Modeling | Mr. Vasanth .B C-CUBE Tekla Software |

| S.NO | Topic | Course coordinator | Internal Faculty members | No. Of students attended | Year | Period |

|---|---|---|---|---|---|---|

| 1 | AUTO CAD & VME001 | Mr.S.A.Gokulakrishnan | Mr.S.A.Gokulakrishnan | 16 | II Mech | 2022-2023 |

| 2 | CREO & VME002 | Mr.P.Sathishkumar | Mr.S.Arunbabu | 30 | III Mech | 2022-2023 |

| 3 | ANSYS WORK BENCH & VME003 | Mr.P.Sabarinath | Mr.L.C.Gokul | 16 | IV Mech | 2022-2023 |

| 4 | AUTO CAD & VME001 | Mr.S.A.Gokulakrishnan | Mr.S.A.Gokulakrishnan | 20 | II Mech | 2021-2022 |

| 5 | CREO & VME002 | Mr.S.Arunbabu | Mr.S.Arunbabu | 7 | IIII Mech | 2021-2022 |

| 6 | ANSYS WORK BENCH & VME003 | Mr.L.C.Gokul | Mr.L.C.Gokul | 7 | IV Mech | 2021-2022 |

| 7 | CAD & VME001 | Mr.P.Ravichandran | Mr.P.Ravichandran | 7 | II Mech | 2020-2021 |

| 8 | CREO & VME002 | Mr.S.Arunbabu | Mr.S.Arunbabu | 23 | III Mech | 2020-2021 |

| 9 | ANSYS WORK BENCH & VME003 | Mr.L.C.Gokul | Mr.L.C.Gokul & Mr.N.Senthil | 60 | IV Mech | 2020-2021 |

| 10 | AUTO CAD & VME001 | Mr.A.Ganesh | Mr.A.Ganesh | 23 | II Mech | 2019-2020 |

| 11 | CREO & VME002 | Mr.S.Arunbabu & Mr.P.Ravichandran | Mr.S.Arunbabu | 69 | III Mech | 2019-2020 |

| 12 | ANSYS WORK BENCH & VME003 | Mr.L.C.Gokul | Mr.L.C.Gokul & Mr.N.Senthil | 60 | IV Mech | 2019-2020 |

| 13 | AUTO CAD & VME001 | Mr.A.Ganesh | Mr.A.Ganesh & Mr.S.A.Gokulakrishnan | 69 | II Mech | 2018-2019 |

| 14 | CREO & VME002 | Mr.S.Arunbabu | Mr.S.Arunbabu & Mr.P.Ravichandran | 80 | III Mech | 2018-2019 |

| 15 | ANSYS WORK BENCH & VME003 | Mr.L.C.Gokul | Mr.L.C.Gokul & Mr.N.Senthil | 93 | IV Mech | 2018-2019 |

| Course Coordinator | Mr. N. Senthil , Mr. A. Ganesh AP/Mech |

| Technical person | Mr. M. Lawrance |

| Internal Faculty members | Mr. S. Arunbabu AP/Mech |

| No of students attended | 42 Students |

| Period | 2017 – 2018 |

| Course Coordinator | Mr. N. Senthil AP/Mech , Mr. A. Ganesh AP/Mech |

| Technical person | Mr. C. Robert |

| No of students attended | 16 Students |

| Placed Students | 16 Students |

| Period | 2016 – 2017 |

| Sem | Sub Code | Sub Name | CO Number | Course Outcomes |

|---|---|---|---|---|

| III | MA3351 | Transforms and differential equations | CO1 | To acquaint the students with Differential Equations which are significantly used in engineering problems. |

| CO2 | Understand how to solve the given standard partial differential equations | |||

| CO3 | Solve differential equations using Fourier series analysis which plays a vital role in engineering applications. | |||

| CO4 | Appreciate the physical significance of Fourier series techniques in solving one and two dimensional heat flow problems and one dimensional wave equations. | |||

| CO5 | Understand the mathematical principles on transforms and partial differential equations would provide them the ability to formulate and solve some of the physical problems of engineering. | |||

| CO6 | Use the effective mathematical tools for the solutions of partial differential equations by using Z transform techniques for discrete time systems. | |||

| III | ME3391 | Engineering Thermodynamics | CO1 | Impart knowledge on the basics and application of zeroth and first law of thermodynamics. |

| CO2 | Impart knowledge on the second law of thermodynamics in analysing the performance of thermal devices. | |||

| CO3 | Impart knowledge on availability and applications of second law of thermodynamics | |||

| CO4 | Teach the various properties of steam through steam tables and Mollier chart. | |||

| CO5 | Impart knowledge on the macroscopic properties of ideal and real gases. | |||

| III | CE3391 | Fluid Mechanics and Machinery | CO1 | To introduce the students about properties of the fluids, behaviour of fluids under static conditions. |

| CO2 | To impart basic knowledge of the dynami cs of f lui ds and boundary l ayer concept. | |||

| CO3 | To expose to the applications of the conservation laws to

|

|||

| CO4 | To exposure to the significance of boundary layer theory and its thicknesses. | |||

| CO5 | To expose the students to basic principles of working of hydraulic machineries and to design Pelton wheel, Francis and Kaplan turbine, centrifugal and reciprocating pumps. | |||

| III | ME3392 | Engineering Materials & Mettallurgy | CO1 | To learn the constructing the phase diagram and using of iron-iron carbide phase diagram for microstructure formation. |

| CO2 | To learn selecting and applying various heat treatment processes and its microstructure formation. | |||

| CO3 | To illustrate the different types of ferrous and non-ferrous alloys and their uses in engineering field. | |||

| CO4 | To illustrate the different polymer, ceramics and composites and their uses in engineering field. | |||

| CO5 | To learn the various testing procedures and failure mechanism in engineering field. | |||

| III | ME3393 | Manufacturing Processes | CO1 | To illustrate the working principles of various metal casting processes. |

| CO2 | To learn and apply the working principles of various metal joining processes. | |||

| CO3 | To analyse the working principles of bulk deformation of metals. | |||

| CO4 | To learn the working principles of sheet metal forming process. | |||

| CO5 | To study and practice the working principles of plastics molding. | |||

| III | ME3381 | Computer Aided Manchine Drawing | CO1 | To acquaint the skills and practical experience in handling 2D drafting and 3D modelling software systems, standard drawing practices using fits and tolerances. |

| CO2 | To prepare assembly drawings both manually and using standard CAD packages. | |||

| CO3 | To Preparing standard drawing layout for modeled parts, assemblies with BoM. | |||

| III | ME3382 | Manufacturing Technology Labarotory | CO1 | To Selecting appropriate tools, equipment’s and machines to complete a given job. |

| CO2 | To Performing various welding process using GMAW and fabricating gears using gear making machines. | |||

| CO3 | Performing various machining process such as rolling, drawing, turning, shaping, drilling, milling and analysing the defects in the cast and machined components. | |||

| III | GE3361 | Professional development | CO1 | Use MS Word to create quality documents, by structuring and organizing content for their day to day technical and academic requirements |

| CO2 | Use MS EXCEL to perform data operations and analytics, record, retrieve data as per requirements and visualize data for ease of understanding | |||

| CO3 | Use MS PowerPoint to create high quality academic presentations by including common tables, charts, graphs, interlinking other elements, and using media objects. | |||

| IV | ME3491 | Theory of Machines | CO1 | To study the basic components of mechanisms, analyzing the assembly with respect to the displacement, velocity, and acceleration at any point in a link of a mechanism and design cam mechanisms for specified output motions. |

| CO2 | To study the basic concepts of toothed gearing and kinematics of gear trains | |||

| CO3 | To Analyzing the effects of friction in machine elements | |||

| CO4 | To Analyzing the force-motion relationship in components subjected to external forces and analyzing of standard mechanisms. | |||

| CO5 | To Analyzing the undesirable effects of unbalances resulting from prescribed motions in mechanism and the effect of dynamics of undesirable vibrations. | |||

| IV | ME3451 | Thermal Engineering | CO1 | To learn the concepts and laws of thermodynamics to predict the operation of thermodynamic cycles and performance of Internal Combustion(IC) engines and Gas Turbines. . |

| CO2 | To analyzing the performance of steam nozzle, calculate critical pressure ratio | |||

| CO3 | To Evaluating the performance of steam turbines through velocity triangles, understand the need for governing and compounding of turbines | |||

| CO4 | To analyzing the working of IC engines and various auxiliary systems present in IC engines | |||

| CO5 | To evaluating the various performance parameters of IC engines | |||

| IV | ME3492 | Hydraulics & Pneumatics | CO1 | To provide the knowledge on the working principles of fluid power systems. |

| CO2 | To study the fluids and components used in modern industrial fluid power system. | |||

| CO3 | To develop the design, construction and operation of fluid power circuits. | |||

| CO4 | To learn the working principles of pneumatic power system and its components. | |||

| CO5 | To provide the knowledge of trouble shooting methods in fluid power systems. | |||

| IV | ME3493 | Manufacturing Technology | CO1 | To study the concepts and basic mechanics of metal cutting and the factors affecting machinability |

| CO2 | To learn working of basic and advanced turning machines. | |||

| CO3 | To teach the basics of machine tools with reciprocating and rotating motions and abrasive finishing processes. | |||

| CO4 | To study the basic concepts of CNC of machine tools and constructional features of CNC. | |||

| CO5 | To learn the basics of CNC programming concepts to develop the part programme for Machine centre and turning centre | |||

| IV | CE3491 | Strenght of Materials | CO1 | To understand the concepts of stress, strain, principal stresses and principal planes. |

| CO2 | To study the concept of shearing force and bending moment due to external loads in determinate beams and their effect on stresses. | |||

| CO3 | To determine stresses and deformation in circular shafts and helical spring due to torsion | |||

| CO4 | To compute slopes and deflections in determinate beams by various methods. | |||

| CO5 | To study the stresses and deformations induced in thin and thick shells. | |||

| IV | GE3491 | Environmental Science & Sustainability | CO1 | To introduce the basic concepts of environment, ecosystems and biodiversity |

| CO2 | To impart knowledge on the causes, effects and control or prevention measures | |||

| CO3 | Ability to understand the performance characteristics of machines | |||

| CO4 | To facilitate the understanding of global and Indian scenario of renewable and nonrenewable resources | |||

| CO5 | To familiarize the concept of sustainable development goals and appreciate the interdependence of economic and social aspects of sustainability | |||

| CO6 | To inculcate and embrace sustainability practices and develop a broader understanding | |||

| IV | CE3481 | Strenght of Materials and Fluid Machinery Laboratary | CO1 | To study the mechanical properties of metals, wood and spring by testing in laboratory. |

| CO2 | To verify the principles studied in fluid mechanics and machinery theory by performing experiments in laboratory | |||

| IV | ME3461 | Thermal Engineering Laboratary | CO1 | To study the valve and port timing diagram and performance characteristics of IC engines |

| CO2 | To study the Performance of refrigeration cycle / components | |||

| CO3 | To study the Performance and Energy Balance Test on a Steam Generator. |

| Sem | Sub Code | Sub Name | CO Number | Course Outcomes |

|---|---|---|---|---|

| V | ME3591 | Design of Machine Elements | CO1 | To learn the various steps involved in the Design Process |

| CO2 | To Learn designing shafts and couplings for various applications. | |||

| CO3 | To Learn the design of temporary and permanent Joints. | |||

| CO4 | To Learn designing and select sliding and rolling contact bearings, seals and gaskets | |||

| CO5 | To Learn designing helical, leaf springs, flywheels, connecting rods and crank shafts for various applications. | |||

| V | ME3592 | Metrology & Measurements | CO1 | To learn basic concepts of the metrology and importance of measurements. |

| CO2 | To teach measurement of linear and angular dimensions assembly and transmission elements. | |||

| CO3 | To study the tolerance analysis in manufacturing. | |||

| CO4 | To develop the fundamentals of GD & T and surface metrology. | |||

| CO5 | To provide the knowledge of the advanced measurements for quality control in manufacturing industries. | |||

| V | ME3581 | Metrology&Dynamics Laboratary | CO1 | To study the different measurement equipment and use of this industry for quality inspection. |

| CO2 | To supplements the principles learnt in dynamics of machinery. | |||

| CO3 | To understand how certain measuring devices are used for dynamic testing. | |||

| CO4 | The students able to measure the gear tooth dimensions, angle using sine bar, straightness. | |||

| CO5 | Determine the natural frequency and damping coefficient, critical speeds of shafts | |||

| V | ME3691 | Heat And Mass transfer | CO1 | To Learn the principal mechanism of heat transfer under steady state and transient conditions. |

| CO2 | To learn the fundamental concept and principles in convective heat transfer. | |||

| CO3 | To learn the theory of phase change heat transfer and design of heat exchangers. | |||

| CO4 | To study the fundamental concept and principles in radiation heat transfer. | |||

| CO5 | To develop the basic concept and diffusion, convective di mass transfer. | |||

| V | ME3681 | CAD/CAM Laboratary | CO1 | To gain practical experience in handling 2D drafting and 3Dmodelling software systems |

| CO2 | Designing 3 Dimensional geometric model of parts, sub-assemblies, assemblies and exporting it to drawing | |||

| CO3 | Programming G & M Code programming and simulate the CNC program and Generating part programming data through CAM software | |||

| CO4 | Design experience in handling 2D drafting and 3D modelling software systems | |||

| CO5 | Design 3 Dimensional geometric model of parts, sub-assemblies, assemblies and export it to drawing | |||

| CO6 | Demonstrate manual part programming and simulate the CNC program and Generate part programming using G and M code through CAM software. | |||

| VI | ME3791 | Mechatronics & IOT | CO1 | Explain Select suitable sensors and actuators to develop mechatronics systems. |

| CO2 | Discuss Devise proper signal conditioning circuit for mechatronics systems | |||

| CO3 | Elucidate the fundamentals ofIot and Embedded Systems | |||

| CO4 | Discuss Control I/O devices through Arduino and Raspberry Pi. | |||

| CO5 | Design and develop an apt mechatronics/IoT based system for the given real-time application. | |||

| VI | ME3792 | Computer Integrated manufacturing | CO1 | Discuss the basics of computer aided engineering. |

| CO2 | Choose appropriate automotive tools and material handling systems. | |||

| CO3 | Discuss the overview of group technology, FMS and automation identification methods. | |||

| CO4 | Design using computer aided process planning for manufacturing of various components | |||

| CO5 | Acquire knowledge in computer process control techniques. | |||

| VI | GE3792 | Industrial Management | CO1 | Discuss basic concepts of management; approaches to management; contributors to management studies |

| CO2 | Discuss the planning; organizing and staffing functions of management in professional organization. | |||

| CO3 | Apply the leading; controlling and decision making functions of management in professional organization. | |||

| CO4 | Discuss the organizational theory in professional organization. | |||

| CO5 | Apply principles of productivity and modern concepts in management in professional organization. | |||

| VI | GE3781 | Mechatronics & IOT laboratary | CO1 | Demonstrate the functioning of mechatronics systems with various pneumatic, hydraulic and electrical systems. |

| CO2 | Demonstrate the microcontroller and PLC as controllers in automation systems | |||

| CO3 | Demonstrate of IoT based Home automation, CNC router, Robotic arm. | |||

| VI | HS8581 | Professional Communication | CO1 | To enhance the learners speaking skill through various activities like group discussion, telephonic conversation, presentation skill etc., |

| CO2 | To develop listening and speaking skills through communicative functions | |||

| CO3 | Enhance the Employability and Career Skills of student | |||

| CO4 | Orient the students towards grooming as a professional | |||

| CO5 | Make them Employability Graduates | |||

| CO6 | Develop their confidence and help them attend interviews successfully | |||

| VII | ME8712 | Technical Seminar | CO1 | |

| CO2 | ||||

| CO3 | ||||

| CO4 | ||||

| CO5 | ||||

| VII | ME8792 | Power Plant Engineering | CO1 | introduce the students the method of oil recovery |

| CO2 | make the students understand the process behavior of some of the important unit operations in petrochemical industry through mathematical model | |||

| CO3 | familirize the students to apply knowledge to select the appropriate control strategy for the selective process | |||

| CO4 | provide information about the most important derivatives obtained from petroleum products | |||

| CO5 | help the students in understanding selection and maintenance of instruments in petrochemical industry | |||

| VII | ME9793 | Process Planning & Cost Estimation | CO1 | know and understand the basics and fundamentals of digital image processing, such as digitization, sampling, quantization, and 2D-transforms. |

| CO2 | Operate on images using the techniques of smoothing, sharpening and enhancement. | |||

| CO3 | Understand the restoration concepts and filtering techniques. | |||

| CO4 | Learn the basics of segmentation, features extraction. | |||

| CO5 | Become familiar with image compression and recognition methods for color models. | |||

| VII | GE8071 | Disaster Management | CO1 | Students will be able to differentiate the types of disasters, causes and their impact on environment and society. |

| CO2 | Students will be able to assess various methods of risk reduction measures | |||

| CO3 | Students will be able to draw the hazard and vulnerability profile of India, Scenarious in the Indian context. | |||

| CO4 | Students will be able to understand and apply government act and information technology during disaster. | |||

| CO5 | Students will be able to do disaster damage assessment and management. | |||

| VII | GE8077 | Total Quality Management | CO1 | Ability to apply TQM concepts in a selected enterprise. |

| CO2 | Ability to apply TQM principles in a selected enterprise. | |||

| CO3 | Ability to understand Six Sigma and apply Traditional tools, New tools, Benchmarking and FMEA. | |||

| CO4 | Ability to understand Taguchi's Quality Loss Function, Performance ,Measures and apply QFD, TPM, COQ and BPR. | |||

| CO5 | Ability to apply QMS and EMS in any organization. | |||

| VII | ME8791 | Mechatronics | CO1 | Ability to understand the fundamental principles of selective analytical instruments used in medical diagnosis, quality assurance & control and research studies. |

| CO2 | Ability to assess and suggest a suitable analytical method for a specific purpose, and evaluate sensitivity, important sources of interferences and errors, and also suggest alternative analytical methods for quality assurance | |||

| CO3 | Ability to critically evaluate the strengths and limitations of the various instrumental methods. | |||

| CO4 | Ability to develop critical thinking for interpreting analytical data. | |||

| CO5 | Ability to understand the working principle, types and applications of NMR and Mass spectroscopy | |||

| VII | ME8711 | Simulation & Analysis Laboratary | CO1 | understand and Programming of PLC, SCADA and DCS |

| CO2 | To working with industrial automation system | |||

| CO3 | To design and implement control schemes in PLC & DCS | |||

| CO4 | To interface field devices with PLC & DCS | |||

| CO5 | To implement the model based control schemes. | |||

| VII | ME8781 | Mechatronics Laboratary | CO1 | Design Instrumentation Amplifier practically for sensor output signal amplification. |

| CO2 | Design active Low pass and High pass filters for filtering the unwanted signals. | |||

| CO3 | Develop various signal conditioning circuit, measure the parameters and comment on the linearity. | |||

| CO4 | Design Linearization and compensation for Thermocouple output. | |||

| CO5 | Design different flow measurement devices. | |||

| CO6 | Draw the piping and Instrumentation diagram for various process and prepare project documentation. | |||

| VIII | GE8076 | Professional Ethicks in Engineering | CO1 | Students will be able to apply the principles of human values and ethics. |

| CO2 | Students will be able to apply the concepts of Professional ideals and virtues. | |||

| CO3 | Students will be able to apply the code of ethics. | |||

| CO4 | Students will be able to evaluate the consequences of safety and risk. | |||

| CO5 | Students will be able to differentiate the responsibility and rights of Engineering professionals. | |||

| VIII | ME8811 | Project Work | CO1 | Experiment a specific problem right from its identification, formulation and obtaining successful solution for the same using various engineering techniques. |

| CO2 | Choose any challenging practical problems and find solution by formulating proper methodology. | |||

| CO3 | Prepare project reports and to face reviews and viva voce examination. | |||

| CO4 | Integrate and work in a team. | |||

| CO5 | Summarize the project and prepare the publication of papers and journals to expose to the technical world. |

| Sem | Sub Code | Sub Name | CO Number | Course Outcomes |

|---|---|---|---|---|

| III | MA3351 | Transforms and differential equations | CO1 | To acquaint the students with Differential Equations which are significantly used in engineering problems. |

| CO2 | Understand how to solve the given standard partial differential equations | |||

| CO3 | Solve differential equations using Fourier series analysis which plays a vital role in engineering applications. | |||

| CO4 | Appreciate the physical significance of Fourier series techniques in solving one and two dimensional heat flow problems and one dimensional wave equations. | |||

| CO5 | Understand the mathematical principles on transforms and partial differential equations would provide them the ability to formulate and solve some of the physical problems of engineering. | |||

| CO6 | Use the effective mathematical tools for the solutions of partial differential equations by using Z transform techniques for discrete time systems. | |||

| III | EI3351 | Analog Electronics | CO1 | Ability Explain the operation and characteristics of PN junction diode, Zener diode, LED and Laser diode. |

| CO2 | Ability To Formulate the expression for voltage gain, current gain, input resistance and output resistance of a BJT CE and CC amplifier using h-parameter model | |||

| CO3 | Ability To Formulate the expression for voltage gain, input resistance and output resistance of FET amplifier under CS,CG and Source follower | |||

| CO4 | Ability To Explain the operation of cascade amplifier, differential amplifier, single tuned amplifier and power amplifiers | |||

| CO5 | Ability To Analyze the operation of negative feedback amplifiers and to design RC and LC tuned Oscillators for a given frequency range | |||

| III | EI3352 | Digital System Design and Applications | CO1 | Ability to Convert various types of codes and number system & gate level implementation of Boolean functions. |

| CO2 | Ability to Apply K –Map for simplification and implementation of combinational logic circuit | |||

| CO3 | Ability to Design the synchronous Sequential logic circuits namely counters, registers etc, | |||

| CO4 | Ability to Analyze the asynchronous sequential circuits and explain the operation of memories and digital logic families | |||

| CO5 | Ability to Design the VHDL coding for combinational logic and Sequential circuits. | |||

| III | EI3353 | Transducers Engineering | CO1 | Understand the working principles of various types of transducers |

| CO2 | Gain knowledge on the application areas of different sensors | |||

| CO3 | Select the right sensor/transducer for a given application | |||

| CO4 | Determine the static and dynamic characteristics of transducers using software packages | |||

| CO5 | Design simple signal conditioning circuits for the R,L and C type of sensors | |||

| III | EI3354 | Linear Integrated Circuits and Applications | CO1 | Explain the IC fabrication process and discuss the fabrication of active and passive components. |

| CO2 | Compute the gain and output voltage of the given Op-Amp circuits. | |||

| CO3 | Explain the internal functional blocks and applications of ICs 555, 566, 565, and AD633 | |||

| CO4 | Explain the operation of voltage regulator ICs namely LM78XX, LM79XX, LM317 and LM723. | |||

| CO5 | Explain the operation and design of various signal conditioning circuits. | |||

| III | CS3353 | C programming and data structures | CO1 | Develop C programs for any real world/technical application. |

| CO2 | Apply advanced features of C in solving problems. | |||

| CO3 | Write functions to implement linear and non–linear data structure operations. | |||

| CO4 | Appropriately use sort and search algorithms for a given application. | |||

| CO5 | Apply appropriate hash functions that result in a collision free scenario for data storage and | |||

| III | EI3361 | Semiconductor devices and circuits laboratory | CO1 | Determine the Breakdown voltage, forward and reverse resistance of PN junction diode and Zener diode and calculate the ripple factor of rectifier circuits with filter. |

| CO2 | Calculate the hybrid parameters of BJT under CE and CB configuration | |||

| CO3 | Obtain the frequency response of CE amplifier and CS amplifier | |||

| CO4 | Obtain the UJT and JFET parameters from the characteristics and also to calculate the gain of differential amplifier using JFET. | |||

| CO5 | Design the RC and LC tuned oscillators for a given oscillating frequency. | |||

| III | CS3362 | C programming and data structures laboratory | CO1 | Use different constructs of C and develop applications |

| CO2 | Write functions to implement linear and non-linear data structure operations | |||

| CO3 | Suggest and use the appropriate linear / non-linear data structure operations for a given problem | |||

| CO4 | Apply appropriate hash functions that result in a collision free scenario for data storage and Retrieval | |||

| CO5 | CO5 Implement Sorting and searching algorithms for a given application | |||

| III | GE3361 | Professional development | CO1 | Use MS Word to create quality documents, by structuring and organizing content for their day to day technical and academic requirements |

| CO2 | Use MS EXCEL to perform data operations and analytics, record, retrieve data as per requirements and visualize data for ease of understanding | |||

| CO3 | Use MS PowerPoint to create high quality academic presentations by including common tables, charts, graphs, interlinking other elements, and using media objects. |